Your Project Is Important To Us

From concept and design – to the finished product – We know just how important your project is to you!

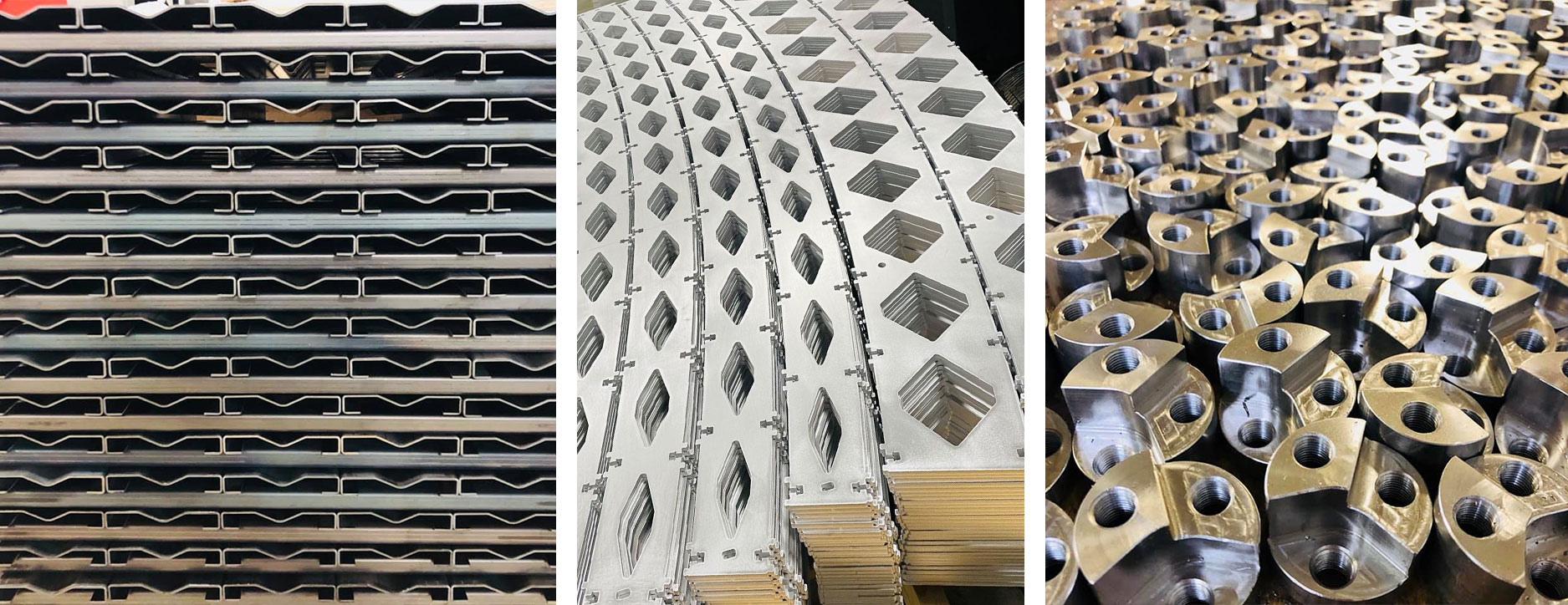

Our highly skilled, dedicated engineering team can write and implement all the necessary programming to run the product you need in our shop. We utilize the latest CAD/CAM technology to streamline the production process and in turn produce consistently accurate, reliable, and in-tolerance parts. The result is a product that meets your specification, at the most affordable cost.

Laser Cutting Services

- Multiple Amada Lasers In-House

- Cutting for a Variety of Different Metals

- Mass Production to Low Volume Runs

- Quick Turnaround Times

Oven Windows

- Roll Forming & Bending, Laser Cutting and Sheet Metal Forming

- Hot Welding of Chrome, Stainless, and Galvanized Material

- Assembly of Oven Window

- Tempered Glass needs: Low-e glass, silk screen glass and curved glass

- We will build to your specifications and/or help you design the widow or door you desire.

Press Brake Services

- 10 ft. Bed Length

- Fixed Height & Common Shut Height

- Tooling to minimize set-up time

CNC Lathe, Milling, Turning, Drilling, Boring, Threading, Tapping, Counterboring, Countersinking, Facing & Broaching Capabilities

Our machining centers are equipped with live tooling capabilities and 3-, 4- and 5 – axis automation to handle simple to complex prototypes and low volume runs.